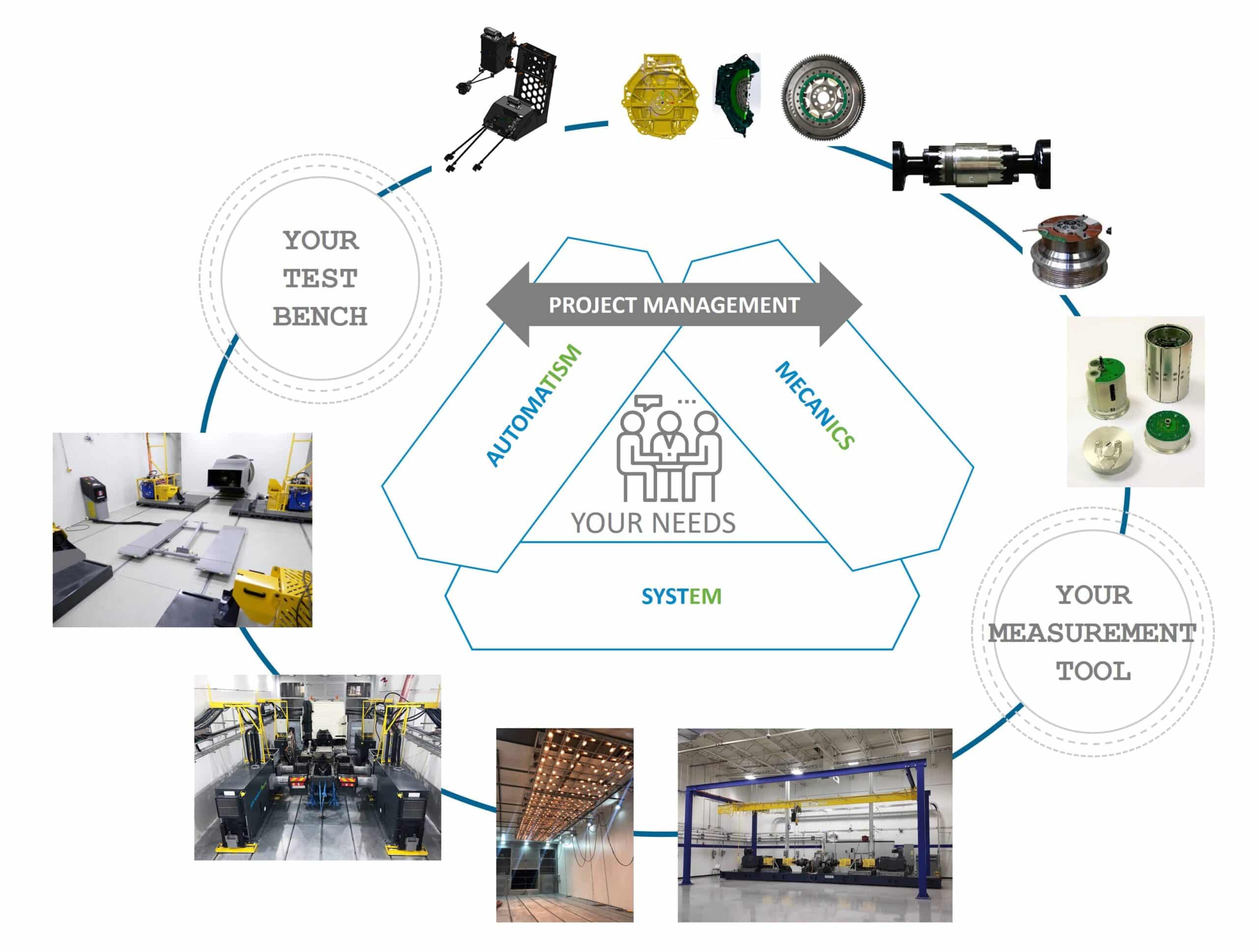

The GREENMOT engineering design office is made up of a set of experts from different specialties who work in synergy to adapt to the needs of each of our clients. We address several types of studies: from an expert consultation on technical specifications to the construction of a customized climatic cell.

Our positioning

Today’s challenges are driving manufacturers, equipment suppliers and manufacturers of all sectors to use increasingly efficient methodologies and test resources that are close to the real environment of use. Our team of engineers supports our customers throughout the V-cycle: from the phase of needs’ definition to the finale training session.

CONSULTING | DESIGN | SIZING| PRODUCTION FOLLOW-UP | ASSEMBLY MONITORING | TRAINING

The team

The different engineering specialities work in synergy to make a success of your project; our experts in automation, system, mechanics, thermal, aeraulics work together to develop your project.

We have also selected a set of trusted subcontractors, with whom we have been working for many years, for the supply of materials, such as SIEMENS for electrotechnical subjects (cabinets, drives, motors).

Our modus operandi

As the first users of the solutions we market, we are able to choose the best compromise between the performance to be achieved and the pragmatic solutions on which to work.

Our aim is to provide you with the benefit of our experience and know-how to maximize your project’s development.

Customer Services

Project Support

Multi-domain skills

System development / Engineering development

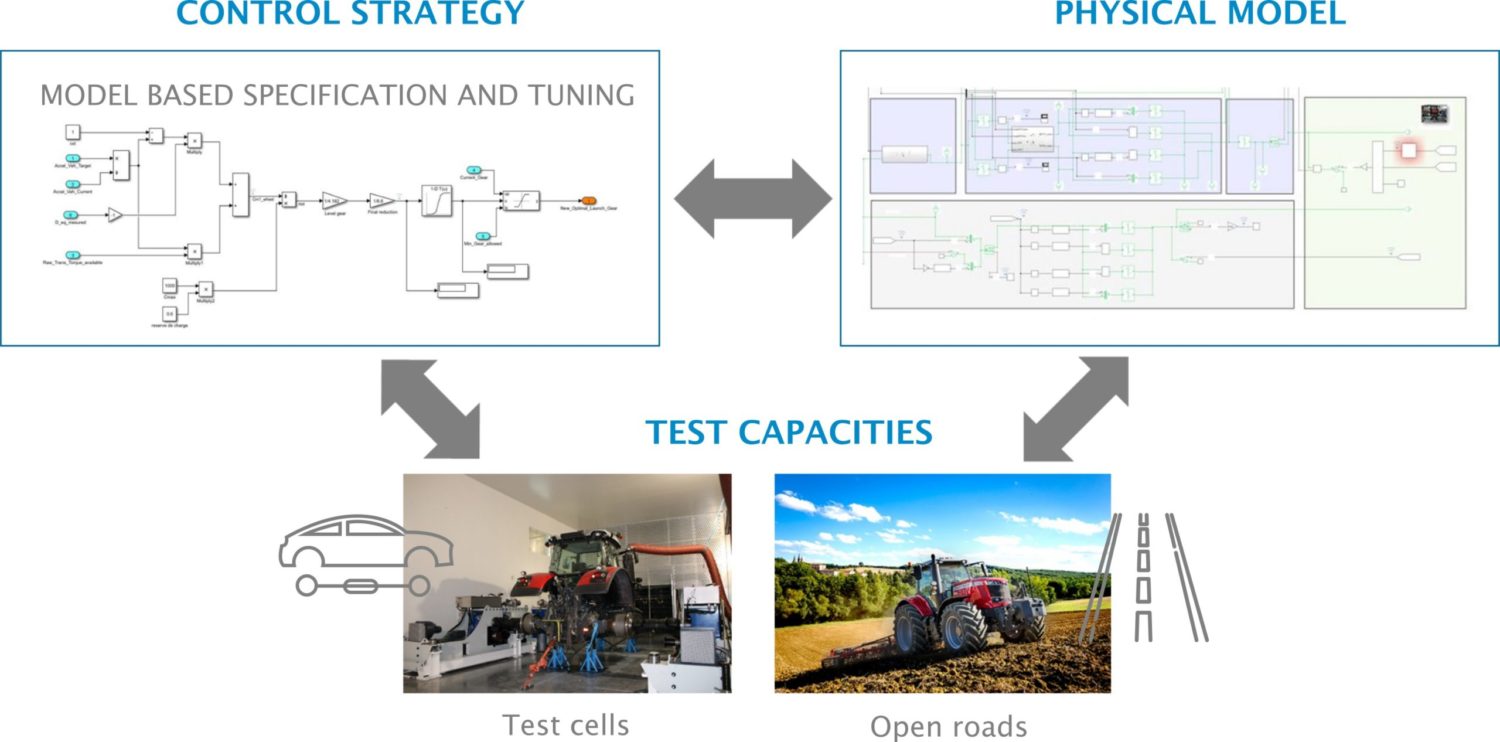

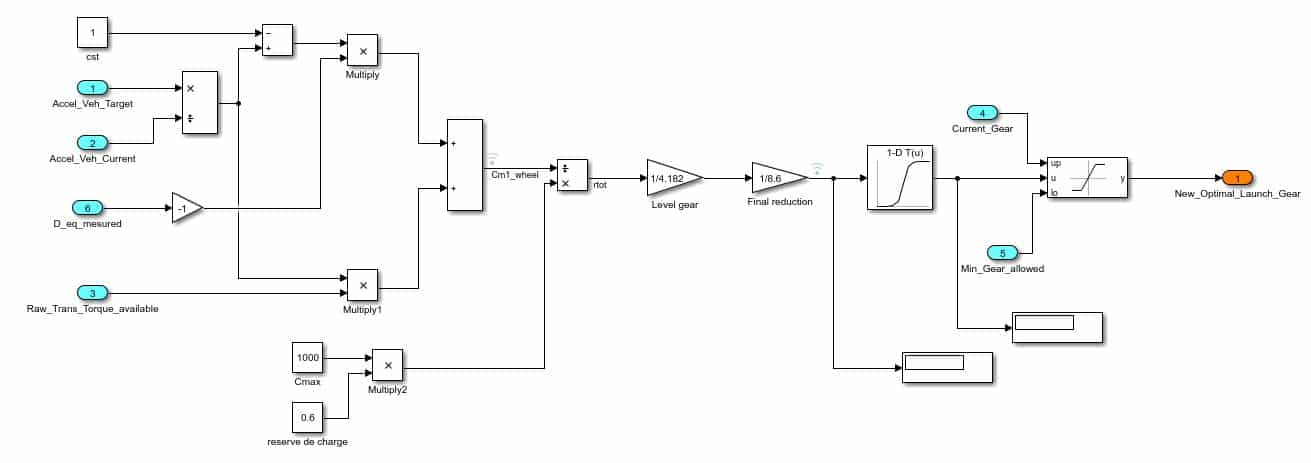

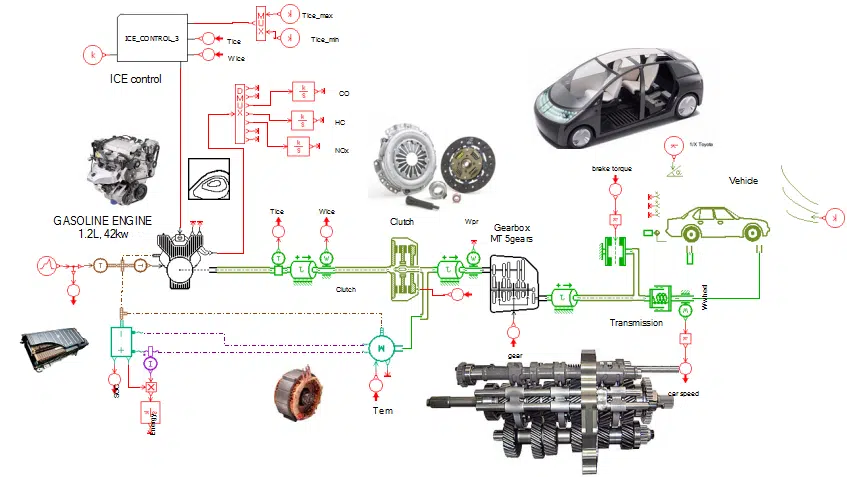

The engineering team uses digital simulation tools to size your products and / or test benches in order to achieve the best performance.

Construction and correlation of models AMESIM / MATLAB / SIMULINK / SIMSCAPE / others.

Technical support: a system approach

Use cases

TEST BEDS | CLIMATIC CELLS | VEHICLE COMPONENT DEVELOPMENT | INNOVATIVE PRODUCT | BESPOKE SENSORS

Support for the development of innovative vehicle functions

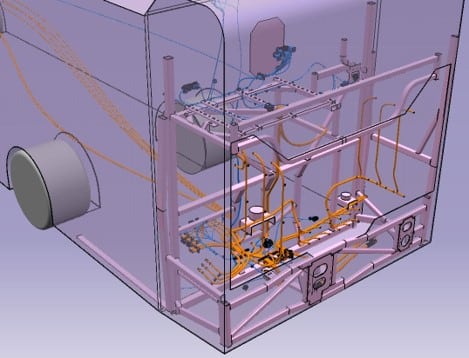

Support in updating test facilities

Definition of renovation’s criterias or test bench update on the following points:

- Ergonomics: installation object to test and piloting

- Energy efficiency

- Aeraulic performances

- Safety & Environmental aspects

CUSTOMER BENEFITS:

- Better test success rate (reliability/robustness)

- Time saved during testing + in data exploitation

- Time to market optimization

Digital model readjustment: « Single test for all vehicle components »

Creation of a digital model representative of the product / vehicle.

Study of possible modifications.

Readjustment of the model according to the results obtained on the different versions.

CUSTOMER BENEFITS:

- Time saving

- Reduction of the risk of error in the choice of the final solution

- Adaptability of the model

- Budget optimization