Why would you renew your test bed?

Investing in a test bench takes up a significant portion of an innovative company’s budget.

Therefor, after a few years, when the test bed tends to become less reliable, the decision of its future becomes central: should it be scrapped or updated? It should also be noted that after a few years of use, the test bench no longer meets the initial needs. So the question remains: should we scrap it or increase its potential?

At Greenmot, we are confronted with this situation regularly, being users of our own test benches.

THE MAIN BENEFICES ARE

IMPROVE SUCCESS RATE FOR YOUR TEST

SAVE TIME ON THE DEVELOPMENT PROGRAM

OPTIMISE TIME TO MARKET

UPDATE YOUR TEST BED TO LATEST STANDARDS

IMPROVE ENERGY EFFICIENCY OF YOUR TEST CELL

How to renew your test bed?

As TIME TO MARKET is key in the multiple energy revolution the Automotive world is currently facing, improving test data quality and analysis time is more crucial than ever. In order to correlate numerical twins with vehicle real behavior, you need to rely on robust, repeatable and reliable testing equipment.

Updating the test bed allows regular maintenance of the installation and in addition, if this option is chosen, a technical upgrade. It is also possible to implement new legal requirements necessary for the safe long-term operation of the test bed.

4 AREAS TO IMPROVE

ERGONOMICS & RELIABILITY

AERAULIC PERFORMANCES

TEST CELL ENERGY EFFICIENCY

SAFETY & ENVIRONMENT

ERGONOMICS & RELIABILITY

- Improved HMI

- Simpler test sequence programming

- Faster Vehicle installation

- Direct Wheel Connection for improved precision

- Better repeatability and automated drive cycle with Robot Driver

AERAULIC PERFORMANCES

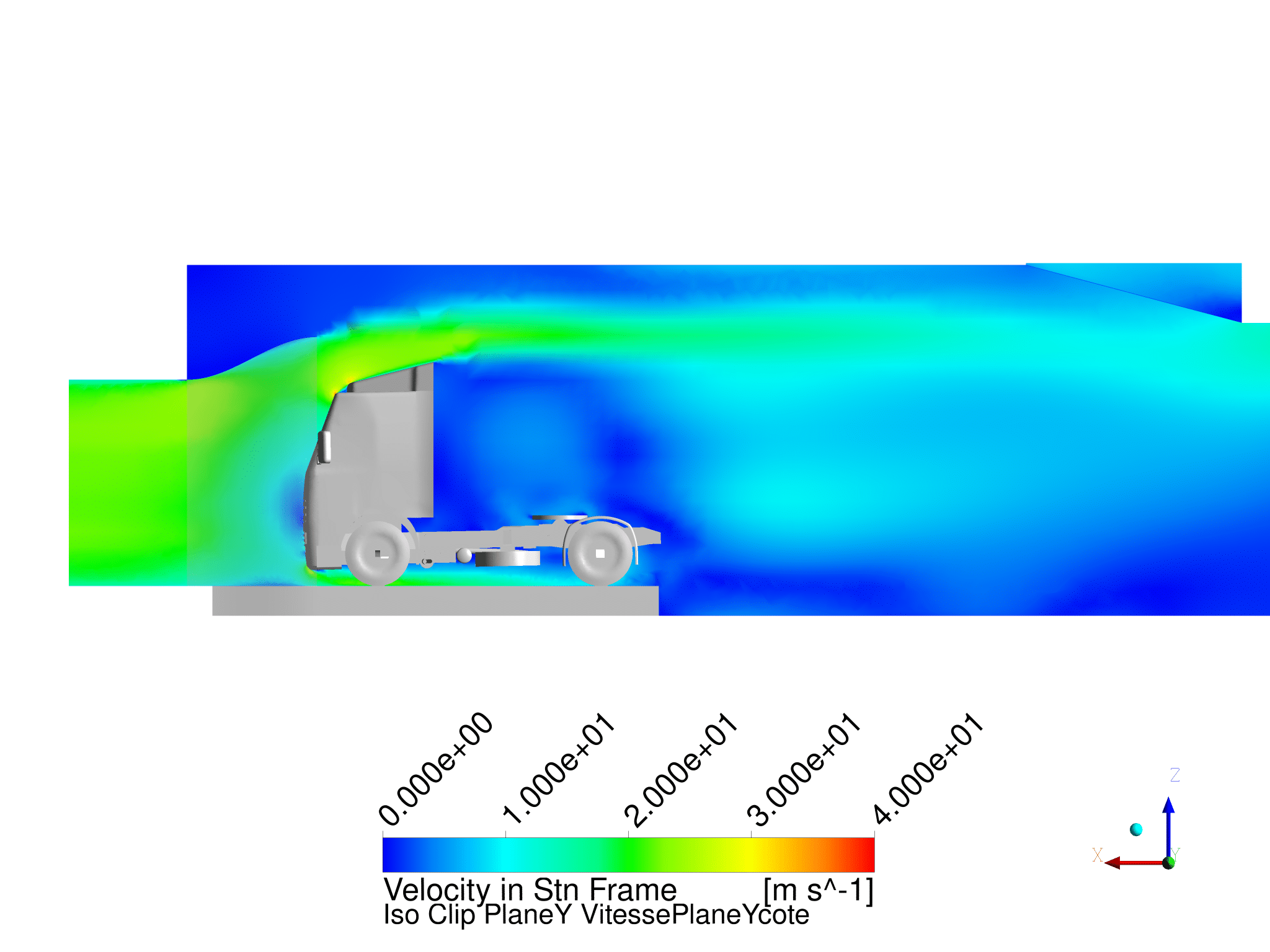

- Model and improve air flux inside the test cell

- Guaranty the right pressure differential between test cell and cockpit

- Improve temperature homogeneity in your climatic chamber

Calcul réalisé en collaboration avec CFD Numerics

TEST CELL ENERGY EFFICIENCY

- Improve or implement Climatic management

- Air inlet preconditioned with double flux cirdulation

- High performance insulation Walls and floor

- Current Reinjection for electricity savings

SAFETY & ENVIRONMENT

- Take into account safety risks related to tested object

- Adapt test cell for H2 vehicles

- Cooling circuit gases conform to latest Fgas legislation

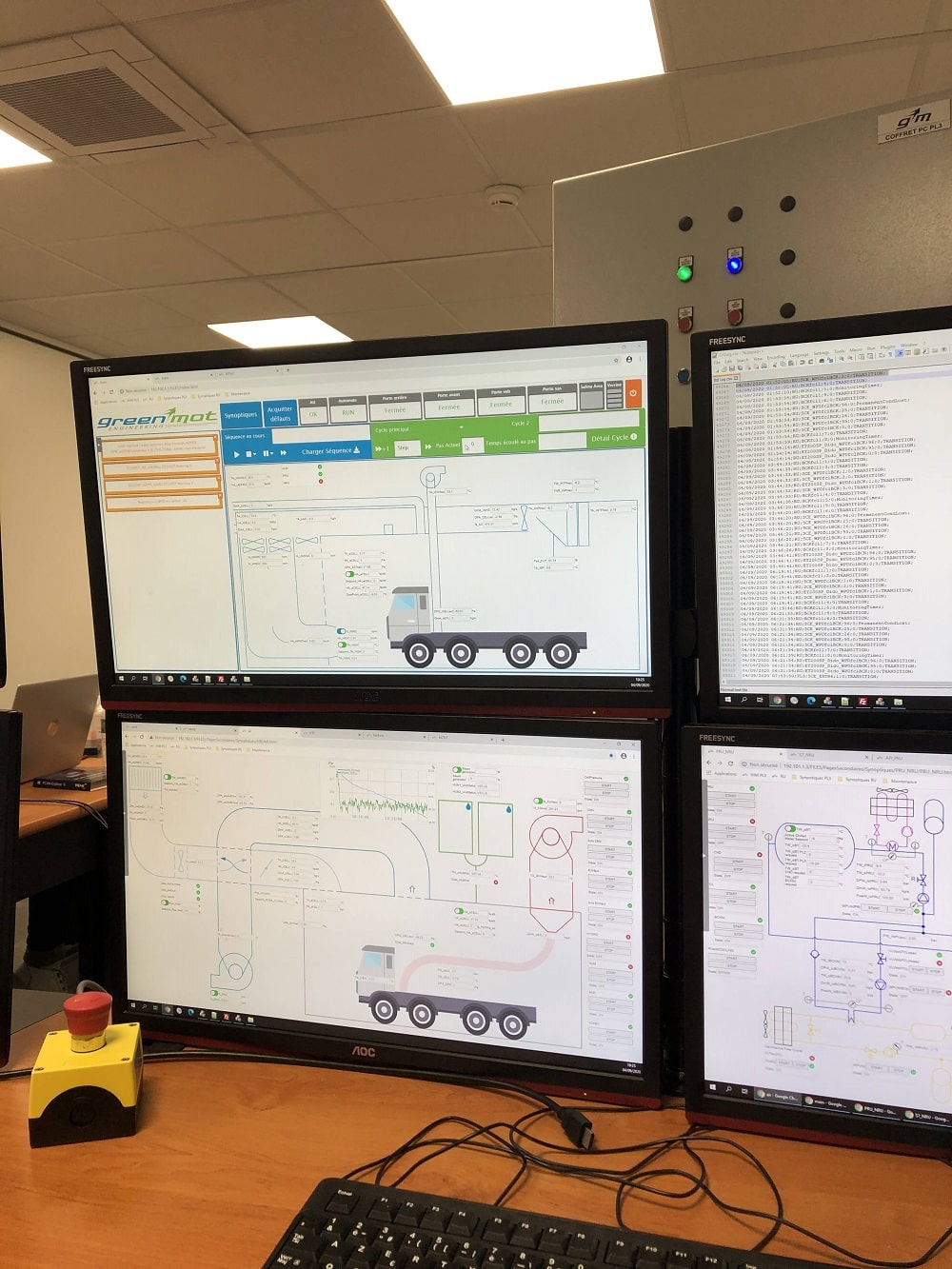

TEST BENCH MANAGEMENT

GREENMOT has developed its own bench control software in order to be able to intervene on all the functionalities, from installation (climate, torque, road law) to operation (test monitoring).

Open Source Software

- No need for long term investment.

GREENMOT web interface

-

Secure internet address directly (no public access).

-

Test program configured on Excel

Integrated features

- Management of test configurations

- Management of test cycles

- Automatic launch of tests and recordings

- Integrated safety management (torques, speeds, etc.)

- Others upon request

Automatic mode

Remote supervision with alert messages: SMS, email, other