Component test benches are manufactured by Greenmot’s team of technicians and engineers.

This teams’ involvement allows to produce specific benches adapted to the needs of the customer.

Component test benches are manufactured by Greenmot’s team of technicians and engineers.

This teams’ involvement allows to produce specific benches adapted to the needs of the customer.

providing the capacity to implement many kind of component test benches (mechanical, transmission, powertrain, cooling pack, exchanger, …)

allowing fine settings and advanced control (acyclism generation, inertia reduction by relative control,…)

GREENMOT is able to specifically implement test bench for many component applications :

Static characterization, quasi-static and/or systems dynamics with possibility of thermal fluids regulation.

RPM mapping / stabilized or transient torque

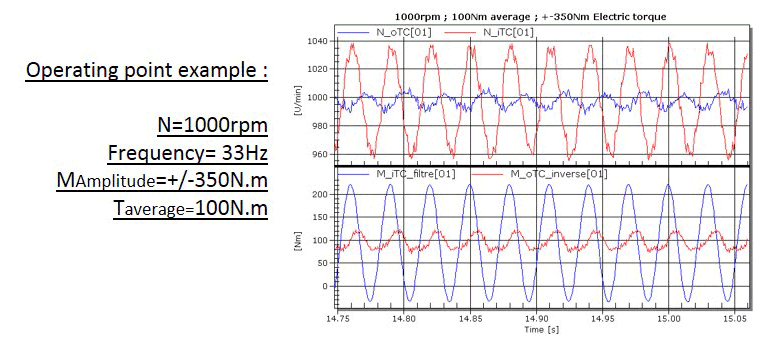

Motor acyclism

Endurance

Many system combinations are possible, including the implementation of low inertia motor :

22 kW, inertia 0.0027 kg.m², max peak torque 150 N.m

22 kW, inertia 0.077 kg.m², max peak torque 190 N.m

37 kW, inertia 0.23 kg.m², max peak torque 450 N.m

These tests can also be realized with thermal fluid and/or aeraulic regulation.

| Aeraulics | 280 kW to 20°C <=> 35 kW to -10°C |

| Maximum air flow | 60 000 m3/h |

| Temperature | -10°C to +45°C |

| Fluid loop | Glycol water 200 kW or oil 10 kW |

| Maximum flow | 70 m3/h |

| Maximum pressure | 6 bars |

| Temperature | -10°C to 90°C |

The component test benches can be implemented in the following areas :

> Passenger cars, off road vehicles (Radiators, groupe de refroidissement)

> Railway, traction transformer (Exchangers, cooling unit)

> Industrial, power transformer (exchangers, cooling unit)