DIRECT 4 WD CONNECTION

TEMPERATURE RANGE : -30°C TO +45°C

0.1% REPEATABILITY ON NEDC, NOW WLTC CYCLES

GREENMOT developed and has operated since 2011, an innovative automotive climatic test cell. This test cell has been designed to provide OEMs and Tier 1 suppliers, large and highly repeatable testing conditions.

This repeatability is especially guaranteed by direct mechanical connection (eliminating tire/roller dispersion) and GREENMOT robot driver (eliminating human driver dispersion). This high repeatability also leads to development productivity savings that makes engineers able to directly identify and quantify the impact of any modification on test results.

TEST CELL TECHNICAL SPECIFICATIONS

TEST CELL SPECIFICATIONS

| Mechanical power | 260 kW |

| Torque per wheel | 2 000 N.m |

| Maximum speed | 145 km/h (16‘’ wheel) |

| Thermal power | 280 kW at 20°C |

| Temperature range | -15°C to+45°C |

| Humidity | Limited 75% of humidity |

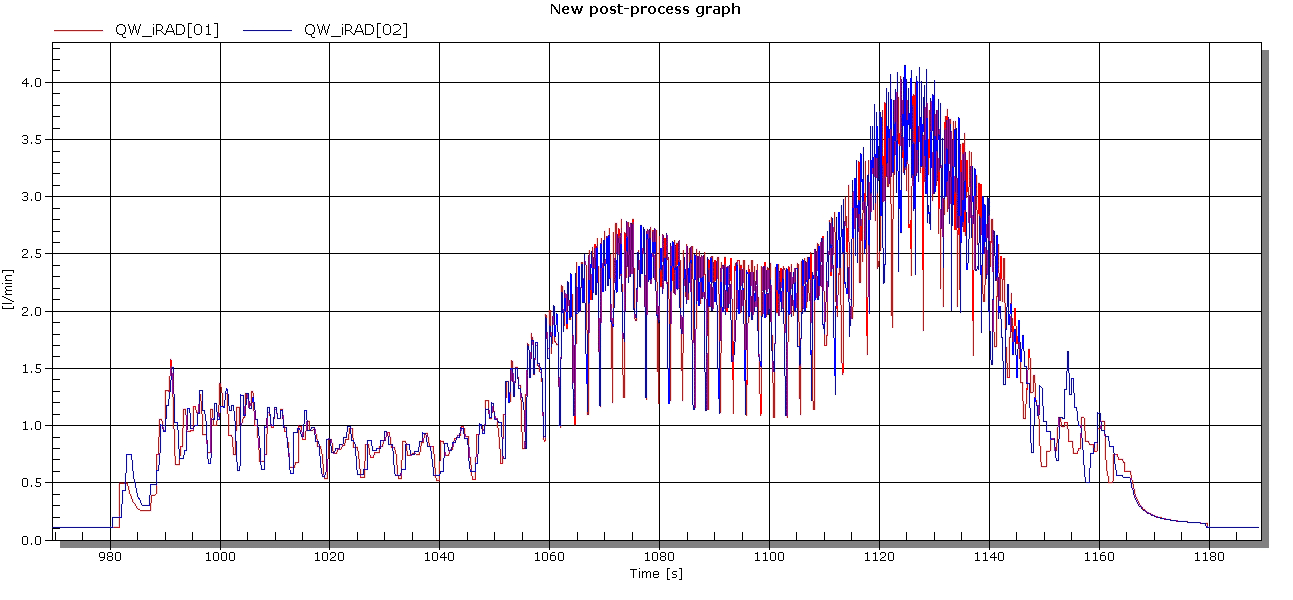

| External fluid control

Including quick cooling capacity |

Coolant temperature control up to 200 kW

2 independent Oil temperature control up to 10 kW |

| Test cell mode | 2 WD /4 WD (with Front/Rear and Right/Left synchronous or independent control) | |

| Control mode | By GREENMOT Robot Driver

Road Load, constant torque or speed, manual control |

|

| Inertia simulation | Up to 4 T | |

| Airflow | 0.5 m² section up to 120 km/h controlled by vehicle speed | |

| Maximum vehicle size | 9m (Length) x 3.5m (Width) x 3,8m (Height) | |

| Maximum vehicle weight | 4 T | |

FUEL & GAS ANALYSIS

| Fuel measurement system | AVL KMA Mobile (High accuracy dynamic mass flow meter) | |

| Combustion analysis | AVL Indimicro 4 channels | |

| Upstream catalyst | AVL AMA i60 THC [60.000ppmC], CH4 [20.000ppmC], NO [10.000ppm] , NOx [10.000ppm], |

|

| CO [10% / 5.000ppm], CO2 [20%], O2 [25%] | ||

| Microsoot sensor AVL 483 | ||

| Gas analysis | Raw gas analysis – Intake Air mass flow meter | |

| EGR | CO2 [20%] | |

| Downstream catalyst | AVL AMA i60 THC [60.000ppmC], CH4 [20.000ppmC], CO [5.000ppm], CO2 [20%] |

|

| Horiba Mexa One QLNX | ||

| NO: 0-10ppm to 0-5000ppm | N2O: 0-10ppm to 0-2000ppm | |

| NO2: 0-5ppm to 0-2000ppm | NH3: 0-5 to 0-2000ppm | |

| Particle counter – AVL 489 | Opacimeter – AVL 439 | |

The automotive test cell can be rent from 1/2 day to several months. The services may include the mandatory or/and necessary instrumentation measurements, if needed.

The applications vary :

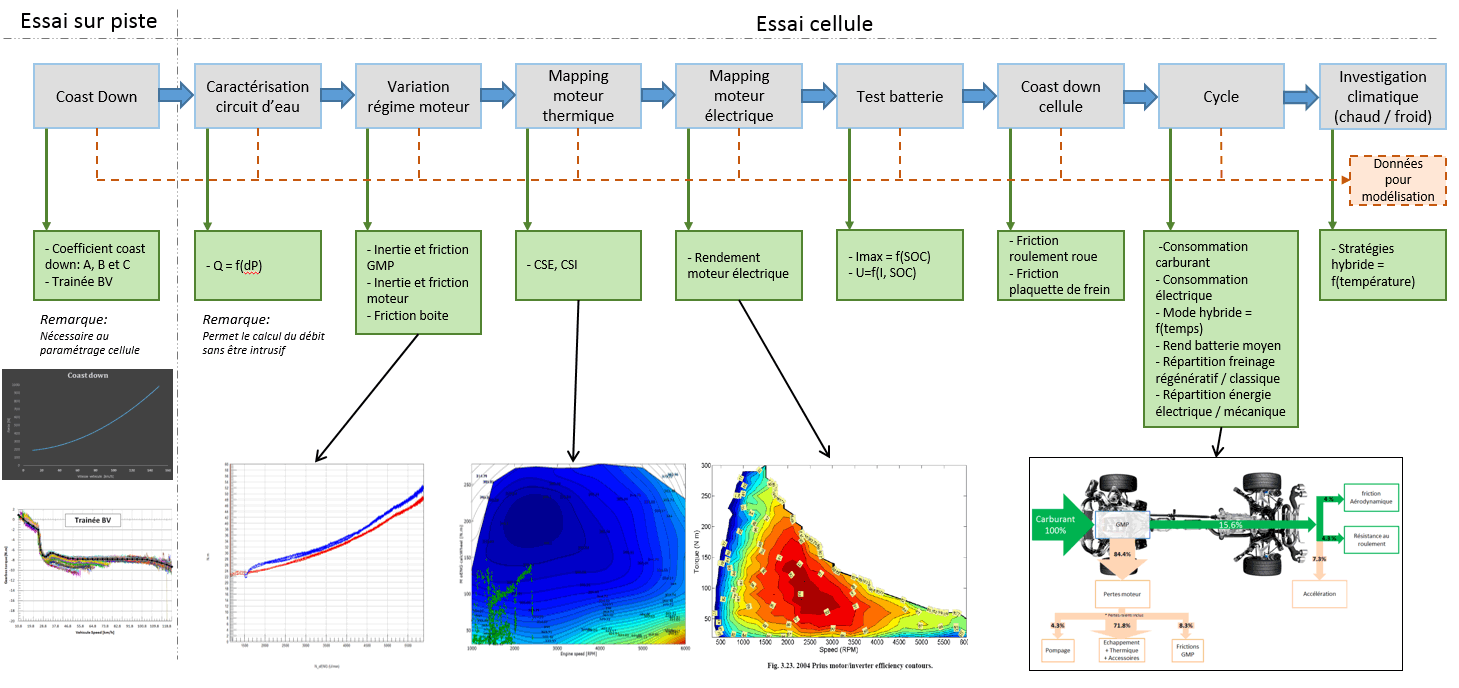

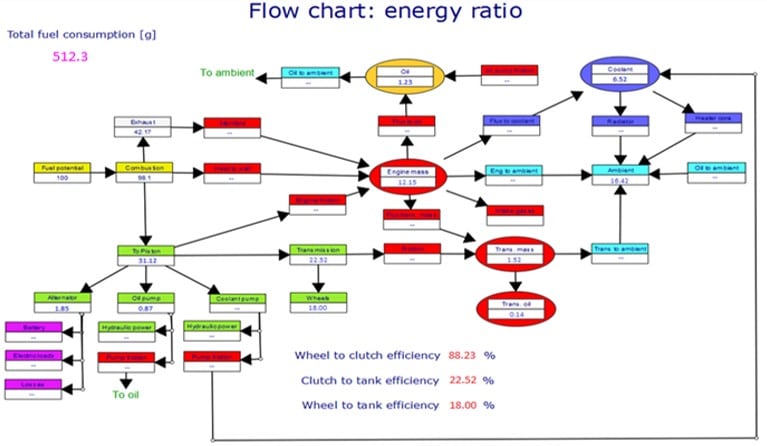

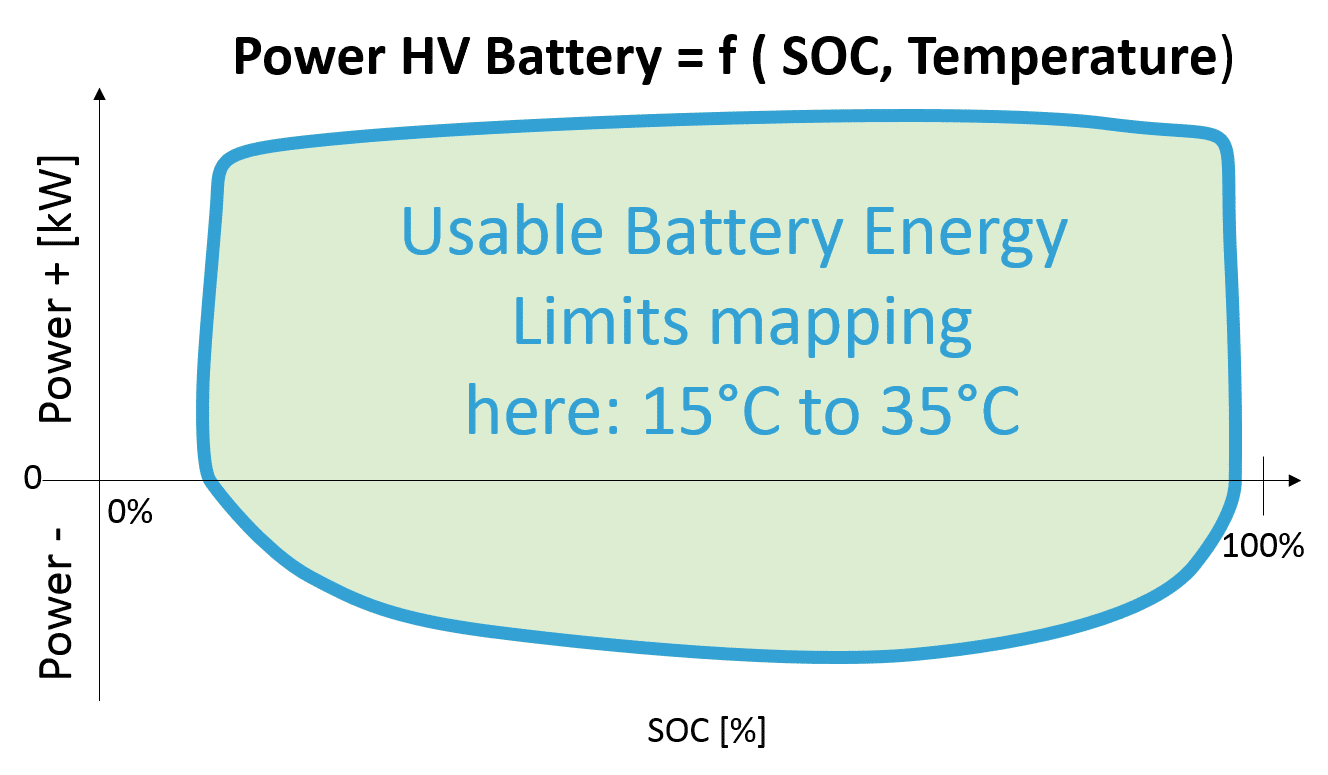

- Energy flow mapping

- Engine mapping

- Hybrid powertrain development

- Traction control

PERFORMANCE | EMISSION | CLIMATIC | AUTOMATIC TESTING | ENDURANCE

Results & Repeatability

The control on the instrumentation and the high repeatability of the results allow to reduce the number of tests carried out by campaign.

Use cases